What is Cathodic protection engineering ?

On global level corrosion occurs on metallic structures, to prevent corrosion, the implementation of cathodic protection engineering is done. Cathodic Protection Engineering extends the service life for metallic structures. Cathodic Protection can be defined as the prevention of electrolytic corrosion of a usually metallic structure such as a pipeline by causing it to act as the cathode rather than as the anode of an electrochemical cell. Globally the leading cause of metallic structure failure is corrosion. The remedy to solve this issue is to apply and monitor cathodic protection systems. CONSULTECH installs effective corrosion prevention systems and monitors their working thus ensuring an effective and efficient cathodic protection system.

The Corrosion Reaction

The Metal corrodes when it reacts with another substance such as oxygen, hydrogen, an electrical current, or even dirt and bacteria. This reaction is own as Oxidation, due to Oxidation in metallic structure corrosion occurring thus reducing the life of the metallic structure.

Cathodic Protection Methods

There are mainly two methods of cathodic protection

- Sacrificial anode method

- Impressed with the current method

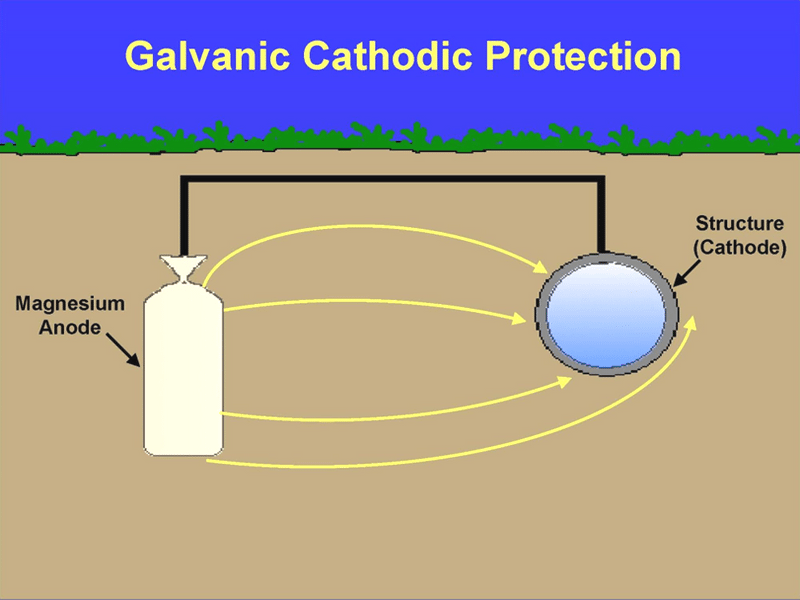

Sacrificial Anode Method

To understand the sacrificial anode method, the concept of galvanic corrosion has to be understood. In any structure, the electrolytes pull out the electrons from the anode metal while flowing toward the cathode metal, as the anode metal begins to oxidize and corrode away. This oxidation process is called galvanic corrosion. This causes the anode component to corrode faster, therefore CONSULTECH installs Anode systems on the metallic structure, so the anode applied by CONSULTECH corrodes rather than the structure hence the name sacrificial anode cathodic protection.

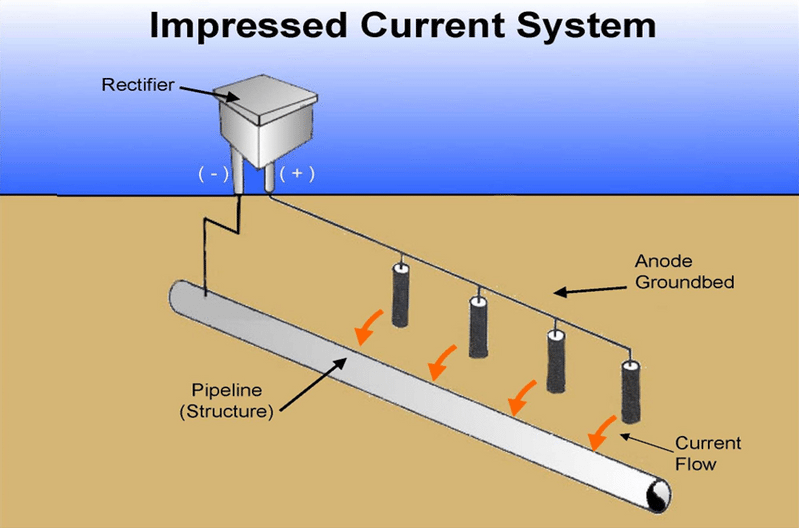

Impressed Current Method

The impressed current cathodic protection system consists of a sacrificial anode system that is in contact with an external power source. The external power supply required is a DC power supply, this power supply provides the electrochemical reaction required for the cathodic protection system to function, in the absence of a DC power supply CONSULTECH provides Transformer Rectifier connected to an AC power supply source. Alternative power sources can also be used as wind or solar.

Types of cathodic Protection system :

Cathodic protection criteria

Corrosion Control

- Inhibitors

- Design

- Materials Selection

- Primary protection technique

- Protective coatings – Barrier, Sacrificial, Inhibitive

- Secondary Protection Technique

- Cathodic Protection – Make Metal A cathode

Annual Loss Due To Corrosion

- U$ 3 Trillion loss to mankind due to Corrosion.

- 40% of Steel is annually reproduced to replace corroding Steel every Year.

- 60% of Maintenance Cost is due to Corrosion.

- U$ 800 Billion can be saved by applying Corrosion Prevention techniques.

- To India 4.5% of GDP is total loss on account of corrosion annually.

- It is Rs.5000,000 Lakh Crores Annually.

Why Corrosion Control Is So Important

- Preserve Assets

- Reduce Maintenance Cost due to Corrosion.

- Reduce Inspection Costs.

- Compliance with Government Regulations.

- Preserve the Environment.

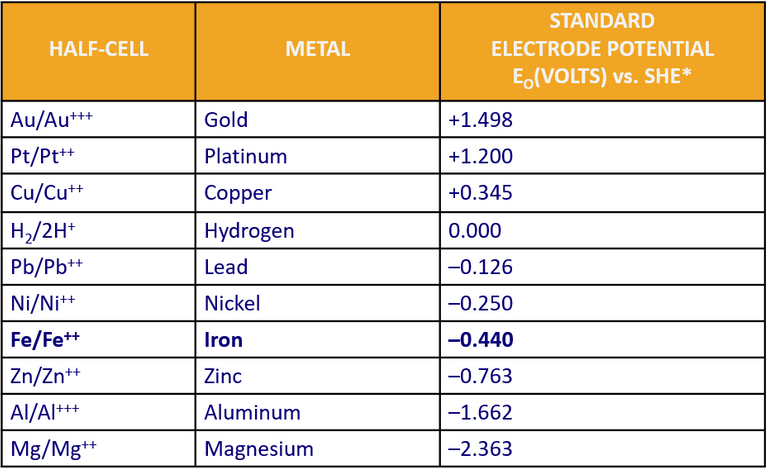

Standard EMF Series of METAL

Corrosion rates of Metal

- Directly proportional to Current Flow.

- Faraday’s First Law – “The weight of any material deposited on the cathode (or liberated from the anode) is directly proportional to the quantity of electric charge passing through the circuit.

- The greater the magnitude of the difference, the higher the current and rate of corrosion.

- Voltage difference is measured between different metals in an electrode or from a metal to a reference electrode both contact the same electrolyte. electrode both contact the same electrolyte.

Corrosion of Metallic Structure

- Uniform attack

- Galvanic corrosion

- Concentration cell corrosion

- Pitting corrosion

- Selective attack corrosion

- Intergranular corrosion

- Stress corrosion

- Erosion corrosion

- Moisture

- Temperature

- Wind

- Chemical contaminants

- Mechanical Loading

Benefits of using Consultech :

- Experience with various kinds of cathodic protection systems spanning over 58 years.

- Cathodic protection system testing, installation, and upkeep experience for all kinds of structures globally.

- NACE corrosion engineers and professionals with high levels of training.

- Team members with prior client-side CP project expertise.

- Having experience leading corrosion divisions of big utilities and pipeline industries and multimillion-dollar CP projects.

- Compared to certain regularly used CP systems, Consultech’s several unique cathodic protection technologies are more affordable and have longer lifetimes.

Your corrosion issues are CONSULTECH’s primary concern. In addition to project management and comprehensive turnkey solutions, we are prepared to help with your requirements for corrosion engineering and field service, including design, production, installation, commissioning, and continuing maintenance. Additionally, we provide a huge selection of unique corrosion protection materials.

Contact our team of corrosion specialists for additional information, to ask a question, or to request a price. Within 24 hours, we’ll give you a call or reply to your email. Call +91 9824077820 for assistance and email consultech_cp@yahoo.com right away