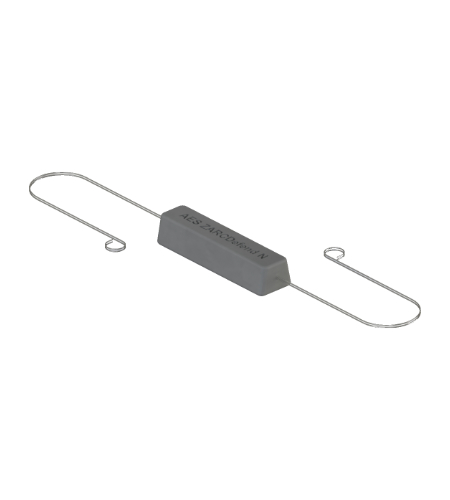

ZARCDefend® N Series

ZARCDefend® N galvanic anode is intended to shield the steel reinforcing in NEW Concrete buildings from corrosion. In order to avoid corrosion of the reinforcing steel, ZARCDefend N embedded galvanic anode devices are used in modern concrete buildings. These Category 1ACC Alkalized anode units are made of high-quality zinc in the pure form that is formed surrounding a steel link wire in a specially designed Alkali Activated cementitious mortar with an interior pH of 14 or higher, which maintains the zinc active state throughout the lifespan of the anode.

Before pouring fresh concrete, ZARCDefend® N anodes are swiftly and simply fitted in the centre of the supporting grid employing further long connection wires to guarantee even current flow throughout the steel. The zinc anode unit primarily corrodes after installation and embedding in the fresh concrete in order to safeguard the nearby supporting steel.

Features and Benefits

- 01 Better lifespan : Full corrosion protection is given for the 10 to 20-year service life of the anode unit. After anode utilization, extended rust prevention is offered thanks to advantageous electrochemical effects according to the galvanic series.

- 02 Type 1 ACC : This Category 1 ACC or alkali-triggered anode units are used to maintain the active state of zinc, and comply with the specifications of construction regulations that forbid purposefully adding components that are toxic to support within the maintenance area.

- 03 3G technology : Offers improved current output and corrosion protection security.

- 04 Turn and Done® : Single wire connection may be installed 2 times faster than the traditional method by saving the cost up to almost 50%.

- 05 Zinc alloy core : High anode utilization and a long-lasting, secure link between the zinc and rebar are both provided by the cast zinc core.

- 06 Steel to Steel Contact : Embedded steel wires make it possible to place an anode quickly and easily. It gives reliable steel-to-steel touch without the use of any auxiliary materials, like galvanizing, which could jeopardize the long-lasting electrical connection. In order to ensure a more uniform spread of charge, prolonged lead cables enable the anode units to be connected in the middle of the supporting grid.

- 07 Versatility : Can be employed with both pre-stressed or post-tensioned concrete as well as traditionally reinforced concrete.

- 08 No Maintenance : Doesn’t call for system tracking or an external electricity supply.

Anode Type

01 Placed in Concrete Repairs.

02 Placed in Drilling Holes in Sound Concrete.

ACC – High pH alkali-activated

Corrosive salts are used to activate HAL-Halides.

Characteristics of Repair Materials

If you want to create an ionically conductive route from the anodes to the base for best results, use ZARCDefend® Embedding Mortar when grouting in anodes in drilled holes.

Applications:

- 01 Reinforced concrete built recently for the long operational life.

- 02 Shielding or security of significant global regions or particular structural components under highly exposed circumstances.

- 03 Protecting key regions like the vicinity of joint extensions where future rusting is likely to occur.

- 04 Used in New structures such as parking garages, bridges, marine structures, water treatment plants, and industrial facilities.

Standard Units :

| Anode Name | Anode Type | Nominal Dimension | Zinc Mass |

|---|---|---|---|

| N | 1ACC | (25mm x 125mm x 25mm) 1 in x 5 in x 1 in |

100 g |

Specification Clause :

An integrated double loop steel tie wire must be the center of embedded galvanic anodes, which must be pre-manufactured with zinc in the manner specified with ASTM B418 Type II and enclosed in a highly alkaline cementitious shell with a pH of 14 or above. According to ACI 562-13, Section 8.4.1, the anode unit must refrain from containing purposely introduced chloride, bromide, or other components that corrode reinforcing steel.

Storage :

In the original unopened box keep it dry and stay away from temperature and humidity extremes. Anodes should be Installed within 2 years.

Health and Safety :

With any cement-based products, contact with moisture can result in the production of alkalis and damage the skin. Appropriate gloves and other protective elements while handling ZARCDefend® anode and ZARCDefend® Embedding Mortar in line with industry standards.