Horizontal Directional Drilling

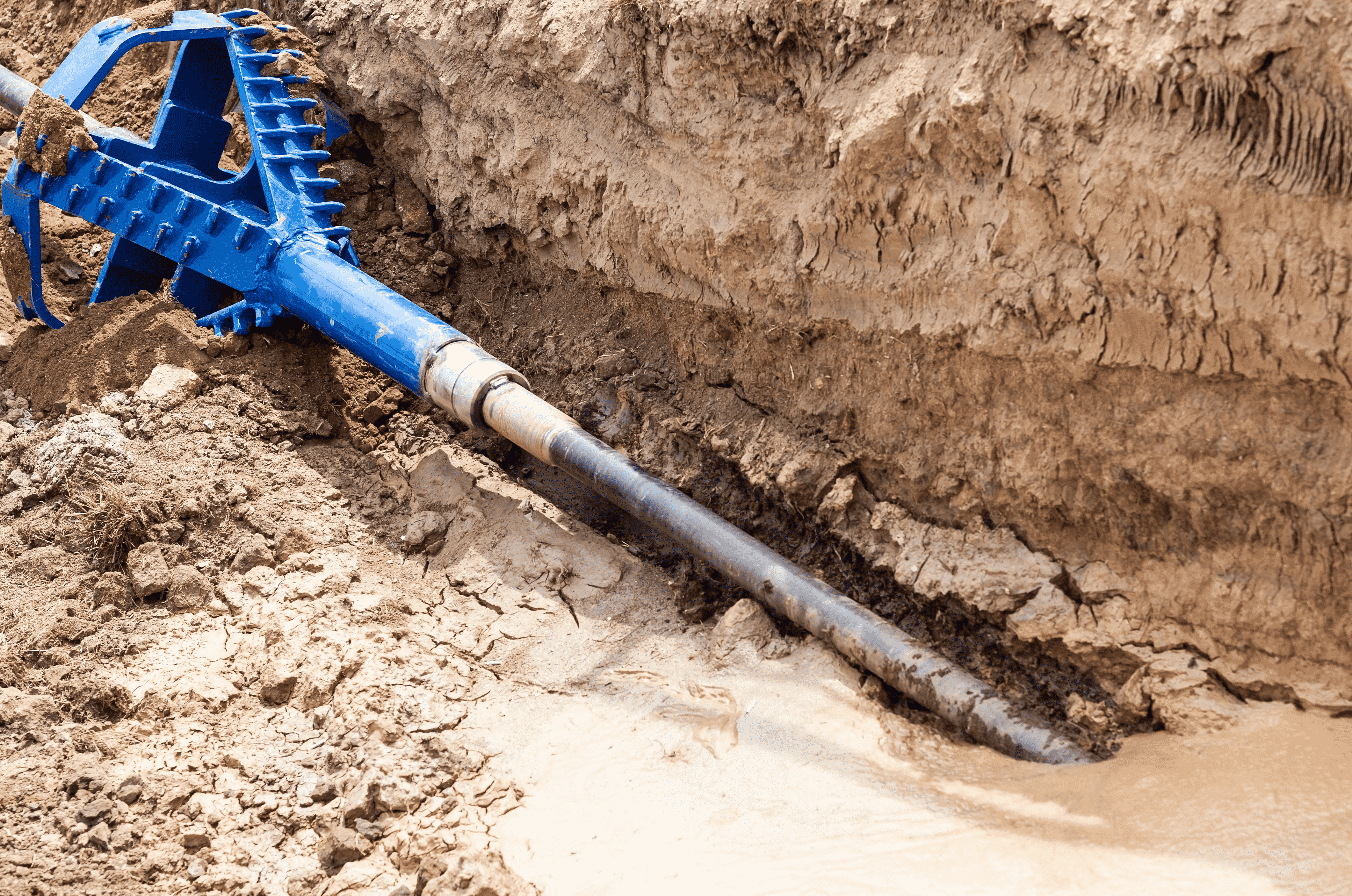

A trenchless technique for installing cathodic protection and AC mitigation systems is horizontal directional drilling, or HDD, commonly referred as directional boring. HDD is frequently appropriate in the following situations:

- Installation is under a road, river, tank or another physical obstacle

- Golf courses, residential neighbourhoods, and environmentally sensitive locations are examples of places where a small footprint and little surface effect are necessary.

- There are right-of-way issues and there is no footprint to install a ground bed

CONSULTECH offers HDD installation services globally for the following clients:

- new bottom cathodic protection systems for above-ground storage tanks

- Upgrade or replace CP systems for old or current storage tanks.

- horizontal ground beds with little influence

- Pipeline casings

- AC mitigation systems

- A variety of other anode installations

Benefits of Horizontal Directional Drilling Installation

Anodes may be put in locations where they cannot be deployed using traditional trenching equipment because to the minimal surface effect of an HDD installation and the ability to drill around structures and barriers. This makes HDD suited for a variety of applications.

In order to place anodes directly or to install slotted plastic pipe, such as PVC or HDPE, into which an anode may be dragged, CONSULTECH offers HDD services. For pulling reference electrodes, we additionally install monitoring tubes (micro-slotted PVC tubing).

Why CONSULTECH?

The HDD drilling market leader in the cathodic protection sector is CONSULTECH. Our substantial fleet of drilling rigs, both vertical and horizontal, is strategically positioned throughout North America and manned by knowledgeable, skilled drilling specialists and construction support workers. Quality cathodic protection systems and AC mitigation systems from CONSULTECH are supported by a world-class team of NACE-certified cathodic protection engineering specialists and a flawless safety record.

Benefits of using Consultech

Your corrosion issues are consultech’s primary concern. In addition to project management and comprehensive turnkey solutions, we are prepared to help with your requirements for corrosion engineering and field service, including design, production, installation, commissioning, and continuing maintenance. Additionally, we provide a huge selection of unique corrosion protection materials.

Contact our team of corrosion specialists for additional information, to ask a question, or to request a price. Within 24 hours, we’ll give you a call or reply to your email.

Call

+919824077820